A milling machine is a versatile and precision-engineered tool designed for accurate material removal and component shaping. Using a rotating cutting tool, it performs a wide range of operations including cutting, drilling, slotting, and surface finishing. Built for reliability and efficiency, our milling machines deliver high accuracy, smooth performance, and consistent results, making them ideal for manufacturing, tool rooms, and industrial production environments.

Process Shaping & Surfacing

TYPE T-200

A friction forging machine shapes or joins metal parts by using friction-generated heat and pressure instead of melting. One part is rotated or oscillated against another to produce heat, softening the material, after which force is applied to forge or bond the parts together. This process creates strong, high-quality components with minimal waste and precise control, commonly used in automotive, aerospace, and heavy engineering industries.

Process Friction Forging

TYPE 4000

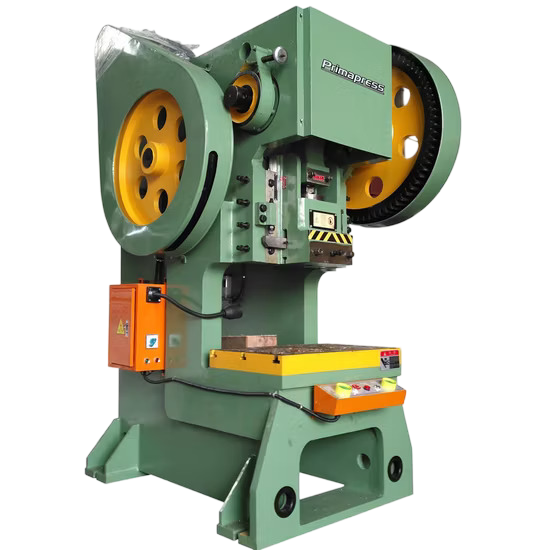

A power press machine is a robust industrial machine used for cutting, bending, punching, forming, and stamping metal sheets with high speed and precision. It operates by applying controlled mechanical or hydraulic force through a die and punch system. Designed for durability and consistent performance, power press machines are widely used in manufacturing industries for mass production of accurate and repeatable metal components.

Process mechanical press

TYPE P-80

A lathe machine is a fundamental precision tool used to shape metal or other materials by rotating the workpiece against a stationary cutting tool. It performs operations such as turning, facing, threading, boring, and drilling with high accuracy. Built for strength and reliability, lathe machines deliver smooth finishes, dimensional accuracy, and consistent performance, making them essential for workshops, tool rooms, and industrial manufacturing.

Process turret lathe

TYPE CB12E3000

A CNC lathe machine is a computer-controlled precision machining system designed for high-accuracy and repeatable turning operations. Using programmed instructions, it automatically performs tasks such as turning, facing, threading, boring, and grooving with minimal manual intervention. CNC lathes offer exceptional consistency, faster production, and superior surface finish, making them ideal for complex components and high-volume manufacturing in modern industrial environments.

Process eco cnc

TYPE 400

A shearing machine is a heavy-duty industrial machine used for cutting metal sheets and plates into precise sizes by applying a straight-line cutting force. It delivers clean, accurate cuts without material deformation and ensures high productivity with consistent results. Designed for strength, safety, and efficiency, shearing machines are widely used in fabrication shops and manufacturing industries for fast and reliable sheet metal processing.

Process mechanical shearing

TYPE jcp 500